Common ball screw terms explained

- pgstechnologies

- Dec 29, 2019

- 3 min read

Updated: Dec 17, 2022

When discussing ball screw assemblies, there is often confusion surrounding common nomenclature used to describe their structure and operation. Circuits, turns, lead, pitch, and starts are all widely used, and misused, terms to quantify various aspects of ball screw assemblies. Although these specifications are related to one another, each has a unique meaning and significance to ball screw design and performance.

Lead and Pitch

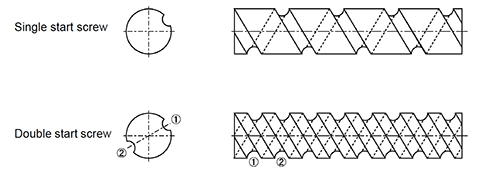

Lead and pitch are a good example of related, but different, specifications. Lead refers to the linear distance traveled for each complete turn of the screw, while pitch is the distance between screw threads. These terms are often used interchangeably, and for single-start screws (see below for definition), lead and pitch are equivalent. However, lead and pitch are not equal for screws with multiple starts.

Circuits and Turns

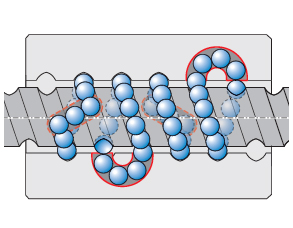

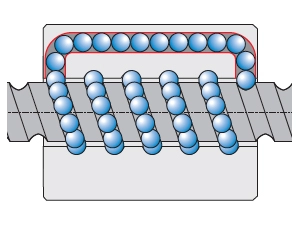

Also related are the concepts of ball circuits and turns. A ball circuit is a closed path of recirculating balls. “Turns” refers to the number of trips the balls make around the screw shaft before being recirculated. The relationship between circuits and turns is influenced by the recirculation method. Ball returns that use the deflector or thread-to-thread (aka cross-over) method recirculate each turn of balls individually. Therefore, the number of turns is equal to the number of circuits.

Internal Deflector Recirculation When balls are returned via an internal channel or an external tube, the recirculating balls can cross several threads, so one circuit can have multiple ball turns. Put another way, the balls will make several trips around the screw shaft before being recirculated. Multi-start ball screw assemblies typically use the internal channel method of recirculation. These can be designed to have multiple circuits, by incorporating more than one internal recirculation channel in the nut body.

Internal End Cap Recirculation

External Tube Recirculation

Starts (and Lead revisited)

Back to lead for a minute. This is an important specification not only for linear travel and speed, but also because a ball screw’s lead determines how many balls are in the load zone (in contact with the screw shaft and ball nut) and, therefore, has a direct impact on load capacity.

Considering the geometry of a screw assembly, it makes sense that as the lead of the screw becomes larger, the number of tracks inside the ball nut becomes smaller, so fewer balls are carrying the load. While larger lead screws offer longer travel per revolution and higher speeds, their ability to provide a high load capacity is compromised. In theory, the number of ball tracks could be increased by making the ball nut longer, but manufacturing constraints and limits on ball nut length make this an impractical solution.

To solve the problem of fewer turns in assemblies with long leads, ball screws and nuts can be manufactured with multiple “starts,” or ball tracks. This puts more balls into the load-bearing zone and increases load capacity.

Multi-start ball screws offer a safety advantage over single-start screws. If one ball track is damaged or experiences fatigue, balls in the other tracks can help prevent catastrophic failure. And, when a single-start ball nut is used with a multi-start screw shaft, the assembly can be refurbished by replacing only the ball nut and not the screw shaft. The new ball nut is installed on the existing screw in the unused track, which saves cost and avoids the need for complete disassembly of the screw system.

While it may seem like an exercise in semantics, understanding these terms and the differences between them can help designers and engineers avoid incorrect assumptions about ball screw operation and performance.

Comments